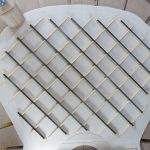

Over the last couple of weeks at home, I finished gluing all the struts of the lattice to the soundboard.

Today, with Roy, I reinforced the spruce struts with carbon fibre, glued kerfed linings to the ribs and made a caul for when clamping the bridge to the soundboard.

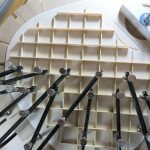

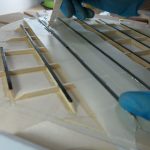

First, I prepared the lattice for the carbon fibre. I ensured each strut was cut to the finished length (in hindsight, I should have done this more accurately when actually making the lattice!), and then I scalloped the ends of each strut before rubbing a sanding bar across the whole lattice to ensure that the struts were sufficiently flat to take the carbon fibre strips.

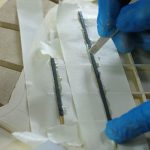

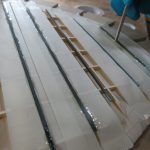

I began by cutting the 1mmx3mm pultruded carbon fibre strips to the correct length for each strut. Then, I masked off two or three struts, mixed a little Araldite Rapid (epoxy adhesive), smeared it on the struts and pushed the strips down, repeatedly checking that they didn’t lift away from the spruce.

The whole process went well, masking and gluing three struts at a time because I was using a fast setting glue (5 mins). I changed gloves regularly so as not to get epoxy everywhere.

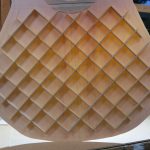

Throughout this, I was talking to Roy about the different approaches Luthiers take to making the lattice: balsa or spruce struts; carbon fibre tow or pultruded strips; a carbon fibre/wood sandwich or just a carbon fibre on top, etc. etc. Roy thinks that this design of lattice using spruce and carbon fibre in only one direction, with a 1 to 1.3mm spruce soundboard, produces the “optimum sound” that he and guitarist, Rob Johns, are looking for. To demonstrate this, he played two of his recent guitars at lunch time. They have good strong bass, mid range and treble. As with all guitars, the quest for that little bit extra from the trebles is always ongoing.

Next, I glued the kerfed linings to the soundboard side of each rib, taking care to ensure they were level with the edge of the ribs. Lots of clamps as usual. I then cut and glued the harmonic bars and will shape them next week.

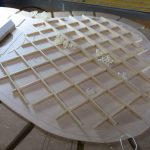

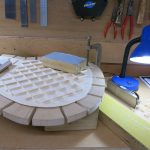

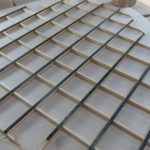

Finally, I made a caul for when gluing the bridge to the soundboard. The lattice pattern and the dome of the soundboard meant that this was probably the most difficult thing to undertake this week. I had to shape the piece of wood to the dome of the soundboard and then cut it to fit the lattice. A unique caul for a unique soundboard.

I bought the soundboard home on the solera to cut it more accurate to size with a scalpel and will begin to piece everything together next weekend.

Except for the lattice, today corresponded to Roy’s book pp. 214-7; 237-9.

When I’m not in the workshop, I’m trying to learn about the physics of guitar construction. Working at a university, I have access to all of the peer-reviewed scientific literature, although the most useful sources so far have been:

Bader, Rolf (2006) Computational Mechanics of the Classical Guitar

Friederich, Daniel (2013) The classical guitar soundboards and their bracing.

Inta, Ra (2007) The Acoustics of the Steel String Guitar.

Rossing, Thomas (ed.) (2010) The Science of String Instruments (Ch.3 with Graham Caldersmith – also published in Fletcher and Rossing’s ‘The Physics of Musical Instruments’).

I’ve not yet read Janssen’s work, but see that it is summarised in Rossing and Caldersmith’s chapter above.

You must be logged in to post a comment.