When he wrote the book, Roy used a brush-applied varnish, so the french polishing section in the book is, by his own admission, very basic. He soon changed to french polish, realising how much better it is. These days, as well as teaching guitar-making, Roy is kept busy teaching French Polishing. On one side of his workshop is a wall of example finishes as well as an outline of the nine stages of french polishing (stage nine, being ‘admire your work!’). Today, I partially reached stage 4 (‘bodying up’).

Stage 1: Surface preparation.

Since last weekend, I had sanded the whole guitar down with different grade papers and brushed on a coat of shellac to pull the grain up. The first thing I did today was rub that down with 240 and 320 papers.

Once the whole guitar had been sanded down with 320 paper, I moved to 1800 micro-mesh and then vacuumed everywhere. Roy then explained the basics of french polishing, the nature of shellac, the reason for mixing it with 99% industrial alcohol (‘meths’), the reason for using a few drops of oil at certain stages of the process, and the importance of creating a well-shaped ‘rubber’:

In the image below, you can see the basic set-up (L-R): 1:4 Shellac/meths mix (250g/1l), meths (for diluting it further), mineral oil, spare meths. The lunch box keeps the rubbers moist when not in use:

Stage 2: Sealing (spit coat): The guitar is rubbed over with shellac (no oil at this stage):

Stage 3: Grain filling: I rubbed over the spit coat with 1800 micro-mesh and then cleaned up with a light wipe of meths.

Roy showed me two methods of grain filling. The first was using ready made ‘grain filler’ (not ‘wood filler’), mixed with liquid dye to get the right colour:

The second method was using pumice. The volcanic rock is abrasive and when rubbed on the wood with a mix of meths, it produced a paste that fills the pores. You can see it working by the colour of the cloth.

Throughout the day, Roy emphasised the importance of squeezing out the shellac so that only a thin coat would be applied:

Stage 4: Bodying up

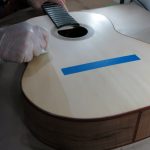

After rubbing over the body and neck with pumice (I didn’t use pre-mixed grain filler), we moved onto the actual polishing of the soundboard (which is close-grained and not filled). I cleaned it over with meths and then, using the rubber ‘charged’ with the shellac/meths solution and a couple of drops of mineral oil, I carefully polished the soundboard in circular and figure-of-eight motions, never stopping on the wood, watching the vapour trail left by the meths. It looked great.

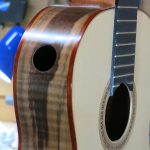

Next, I returned to the body and rubbed down the pumice filler with 1800 micro-mesh. At times, I’d applied it a bit heavy and had to resort to 320 paper to cut it back. The result at the end of today was a soundboard with one session of polish and the body rubbed down ready for polishing. I’ll repeat stage 4 everywhere several times over the next week.

Stages 4-6: Bodying up, stiffing, spiriting off. With terms like this, I feel I have stepped into some kind of ancient guild…

At home, I finished the first session of ‘bodying up’ and ‘stiffing’ (apparently, ‘stiffing’ with meths removes the oil and flattens the shellac)’, completing the back, sides, neck and bridge. The next morning, I completed a second session.

Before the second session, I lightly rubbed 1800 micromesh over the whole guitar and bridge and then wiped it with a cloth with a few drops of meths added (spiriting off).

The polishing session involved charging the rubber with shellac solution, diluted 3:1 with a little meths, squeezing out, then adding a drop of oil. I rubbed the surface of the guitar until the rubber felt ’empty’, confirmed by pressing it against paper leaving barely any mark. I repeated this until the whole guitar was covered and left it half an hour. Then, I took a few drops of meths on a clean rubber and wiped the whole guitar over to remove the oil (‘stiffing’).

Roy has given me detailed instructions on the whole polishing process and suggested that I give it six of the above sessions before moving to the next stage.

Today corresponds to Roy’s book pp. 314-316.

You must be logged in to post a comment.